- Top

- Technical Info

- What is a connector

What is a connector

A connector is a component that forms an electronic/electrical circuit through electrical connections.

The word "connector" means "something to connect", and it is used for various things today.

Connectors that connect water pipes and air cylinders, connectors that connect web data, and recently jobs and titles that connect people and jobs are also called connectors.

IRISO, we manufacture and sell electrical connectors, which are the most popular types of connectors. We will introduce how the connector, which connects electricity between "something" and "something", has changed and evolved since its origin, and IRISO 's efforts.

- Birth of the connector

- Diversification of connectors

- IRISO 's "Reliable Connection" Efforts

- Technology pursued by IRISO

A broader description of the connector

- Options to improve connector reliability

- How to mount the connector on the board

- About WtoB connector and IF connector

- Board to Board Connectors connection form and Floating structure

- About Compression Terminal

- Types and features of FPC / FFC Connectors

Birth of the connector

When and for what purpose was the connector born?

It is said to have started during the Second World War.

A variety of electronic devices were developed one after another due to military demand against the backdrop of war. The developed equipment is used in harsh environments. However, every time there was a breakdown, I had to bring the "set of equipment" to the repair shop. This is especially difficult with large equipment. It cost a lot of money every time, and even when the time was of the essence, it took a lot of effort, effort, and time. And even if you do a backup, it was necessary to have a "complete set of equipment".

At that time, I was motivated to "replace only the broken parts" in order to simplify repairs. Therefore, it is said that the desire to make the parts that were connected by soldering a "detachable electrical connection," and the connector was invented and started to be used as a means to realize this.

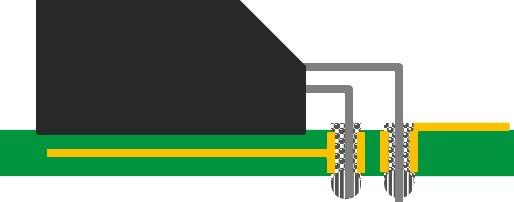

The first connector developed was a detachable wire that was soldered and terminated. After that, the synergistic effect of the popularization of printed circuit boards and the invention and development of various electronic components changed the shape greatly.

Diversification of connectors

Visible external connector

Connectors are classified into those used outside to connect devices and units, and those used to connect inside devices and units, mainly between boards and parts. Connectors were born in the form of connecting electric wires, but the form of connecting outside the equipment is still the mainstream today. With the advancement of advanced functions, there are many things that everyone has a chance to see, such as things that connect to outlets, USB and network connectors.

Internal connector used in equipment

On the other hand, the spread of printed circuit boards has become an epoch-making (epoch-making invention) for devices used inside equipment, and several other forms of alternatives have been invented and spread. I'm coming. For example, connectors called "board-to Board to Board Connector" and "board-to-board" that connect one board to another board, and flexible printed circuit (FPC), which was invented as a flexible printed circuit board. In addition, a connector was born that connects an alternative to FPC via FFC (flexible flat cable) made by a more electric wire manufacturing method.

IRISO Connector

IRISO manufactures and sells "Board to Board Connector" connectors and "FPC connectors" as our main products.

For the outside of the equipment, we have mainly developed what is called an "interface connector" for automobile parts, and recently we have also put connectors for electric wires on the market.

Nevertheless, we believe that providing connection solutions inside equipment is a feature and strength of IRISO.

What does “reliably connect” mean?

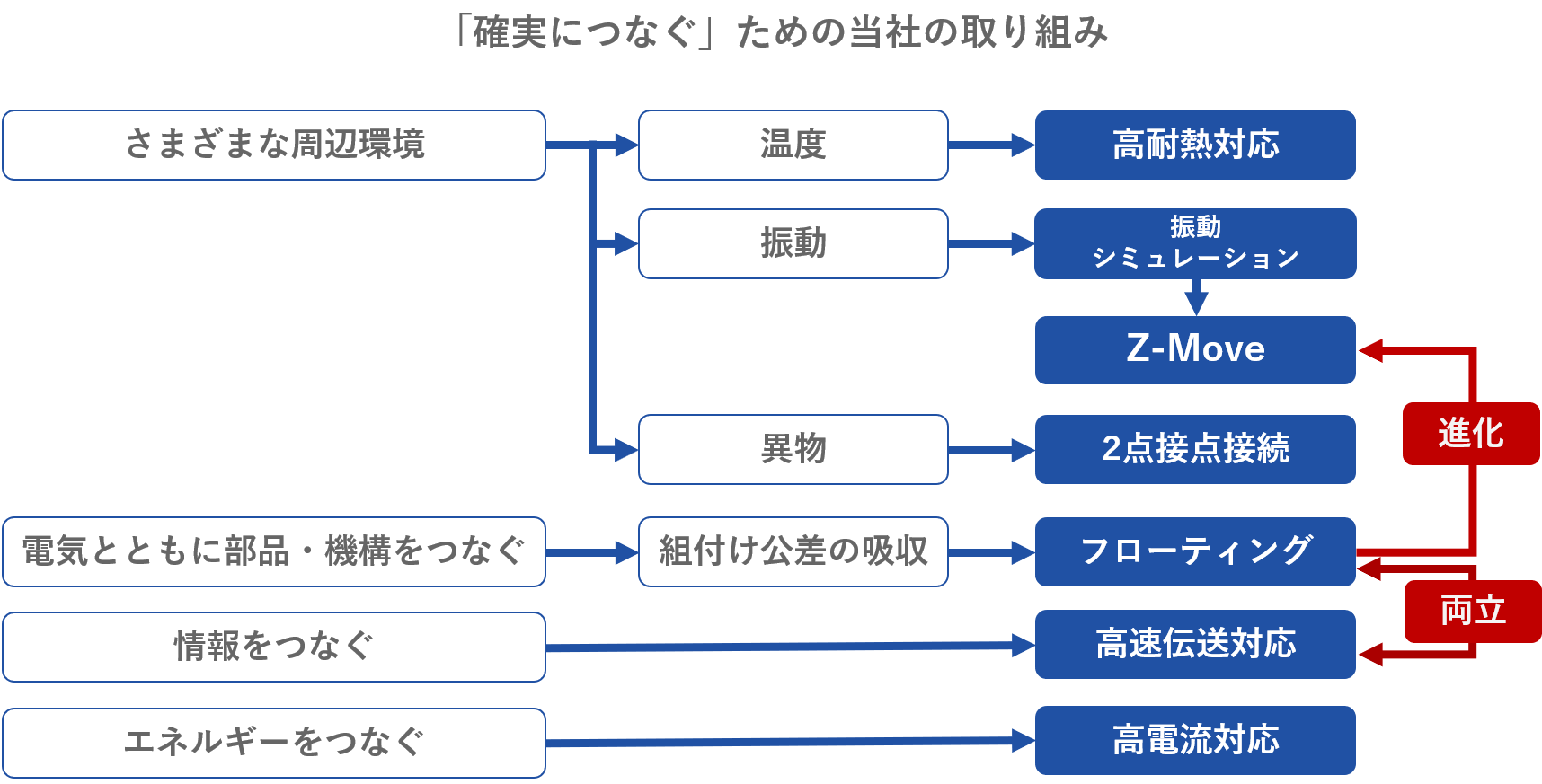

Now, I would like to introduce what IRISO is doing to provide the function of "reliable connection".

I think that many people of a certain age are familiar with the phenomenon that "If you hit it with an old electronic device, it will be cured." Most of them are caused by defective connectors and cracks in the solder where the connectors are mounted. It can be said that this is an example of not being able to realize "reliable connection" and "reliable connection".

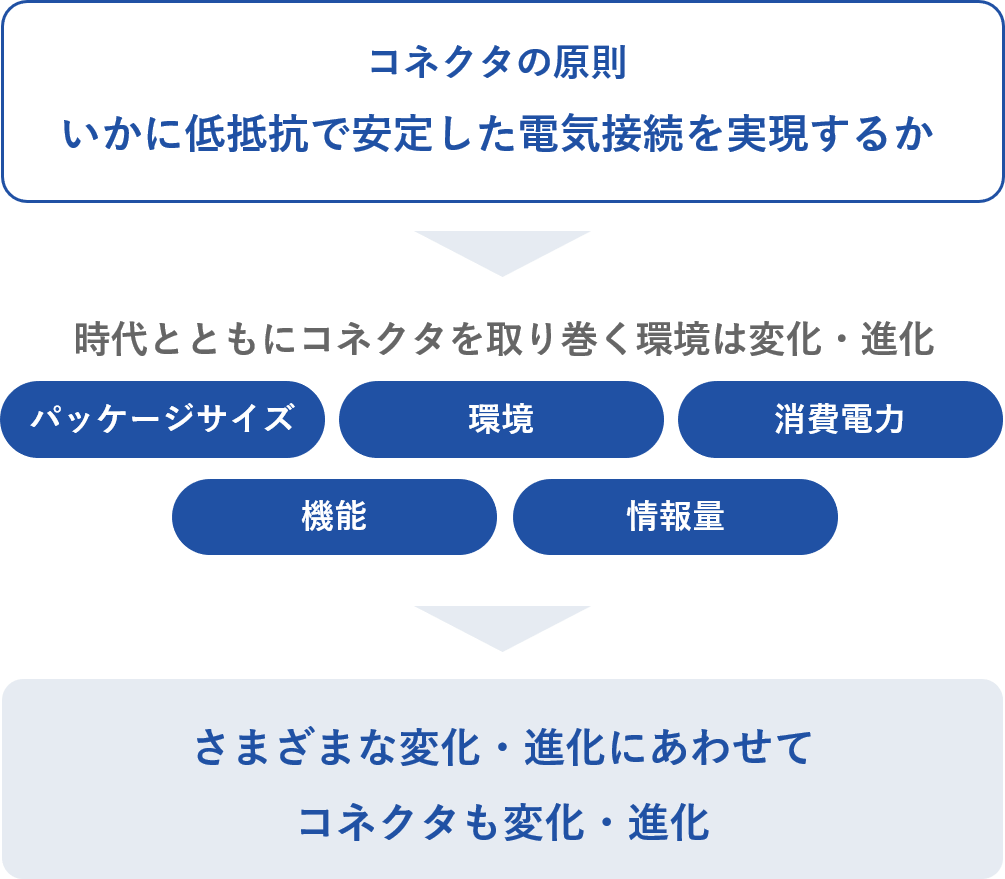

The principle of connectors is "how to achieve a stable electrical connection with low resistance". Since the time of its birth, what a connector should connect to has been constantly changing, such as the size of equipment, the diversification of functions, the advancement of functionality, the increase in the amount of energy required and the amount of information to be communicated. I'm here. Component configurations have become more complex, requiring high-density mounting and assembly in various forms. High functionality requires a huge amount of energy, and at the same time, temperature rise is an unavoidable issue.

Responding to diversification of connections

In the midst of such constant change and evolution, IRISO believes that "reliable connection" means:

① In various surrounding environments

② Keeping in mind to connect parts and mechanisms together with electricity

③ Connecting increasing information and energy

That's what it means.

As efforts to realize this, we will introduce an overview of High heat-resistant Connector, two-point contact connections in connectors, Board to Board Connector with a Floating structure mechanism, and support for high-speed transmission in Floating Connector. increase.

Technologies pursued by IRISO

High heat-resistant Connector

Background of demand for High heat-resistant Connector

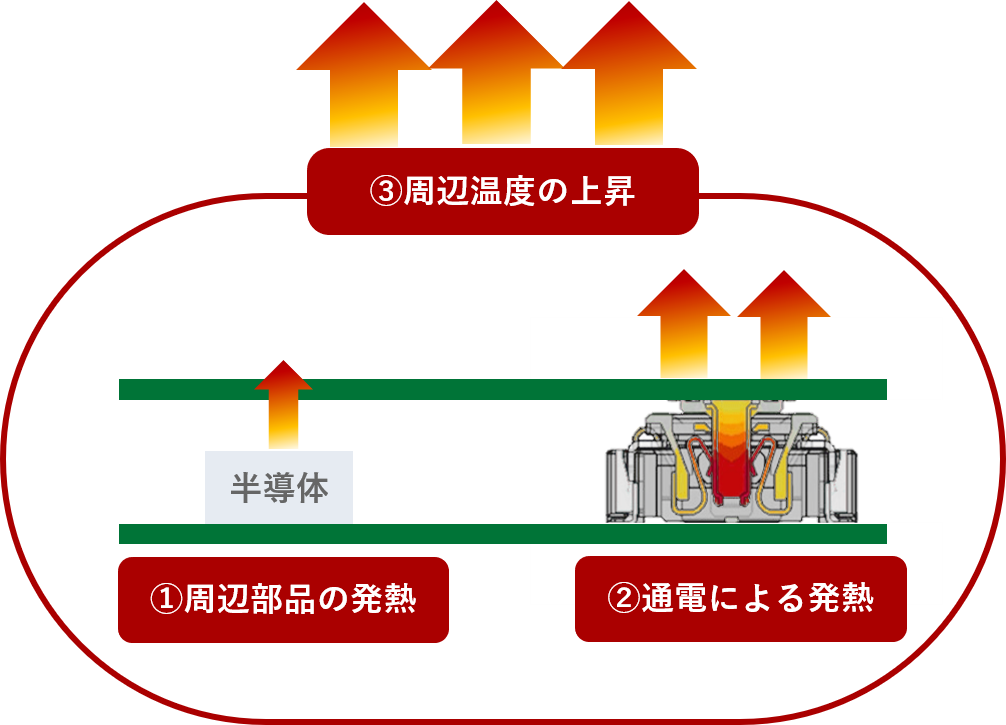

In recent years, heat resistance requirements for connectors have been steadily increasing. Why is heat resistance necessary and is the demand becoming more stringent?

The reason lies in the installation environment.

The amount of heat generated from semiconductors, etc., is increasing year by year due to the increasing functionality and frequency of devices in recent years. In addition, the area around the engine of a car, for example, becomes particularly hot. Due to the influence of these peripheral components, connectors must perform the function of connection at high temperatures.

Furthermore, there is also heat generated by the energization of the connector itself. Connectors are usually rated for a current value that rises by 30°C, but it is necessary to have heat resistance that takes into account all of these.

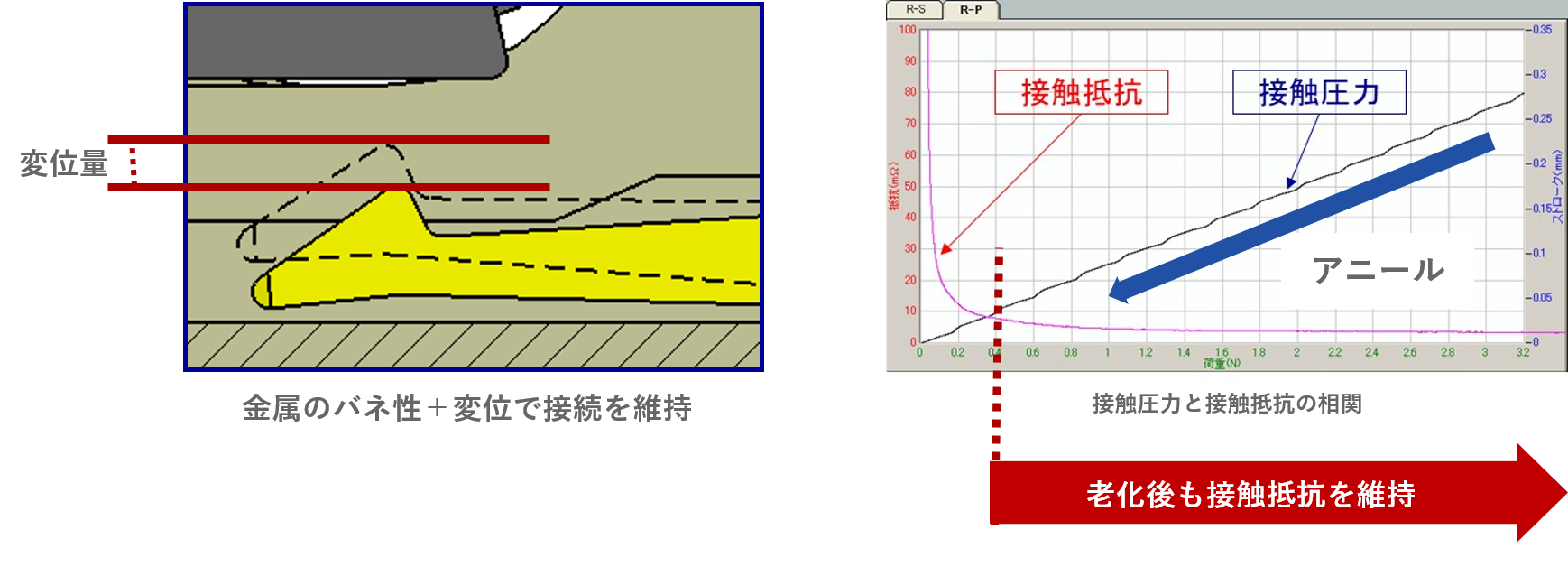

What you need for a stable connection at high temperatures

For heat resistance, maintaining contact resistance in high temperature environments is particularly important. Connector terminals, the so-called connection parts, are mainly made of copper alloy. Contact resistance depends on the contact pressure between terminals, but it is usually established by having a spring mechanism on one or both sides of a pair of connectors. Metals undergo a softening phenomenon called "annealing" at high temperatures. Originally, connector terminals maintain springiness by having a certain amount of "strain" as metal, but at high temperatures, the "strain" is removed and the springiness weakens.

During this weakening process, it is necessary to achieve consistent and proper contact pressure over a given product life and within limited space and cost. The initial contact pressure should not be too strong, as too much pressure will make Mating difficult. On the other hand, maintain the necessary contact pressure even if the annealing progresses. To that end, in addition to selecting the appropriate metal material, it is important to design technology for terminal shapes that incorporate various ingenuity.

IRISO, we have released a large number of High heat-resistant Connector by implementing a lot of know-how and evaluation methods that we have cultivated so far, as well as CAE as appropriate. Our products have a maximum rating of 125°C, and we have both Board to Board Connector and FPC connectors.

2-point contact connector

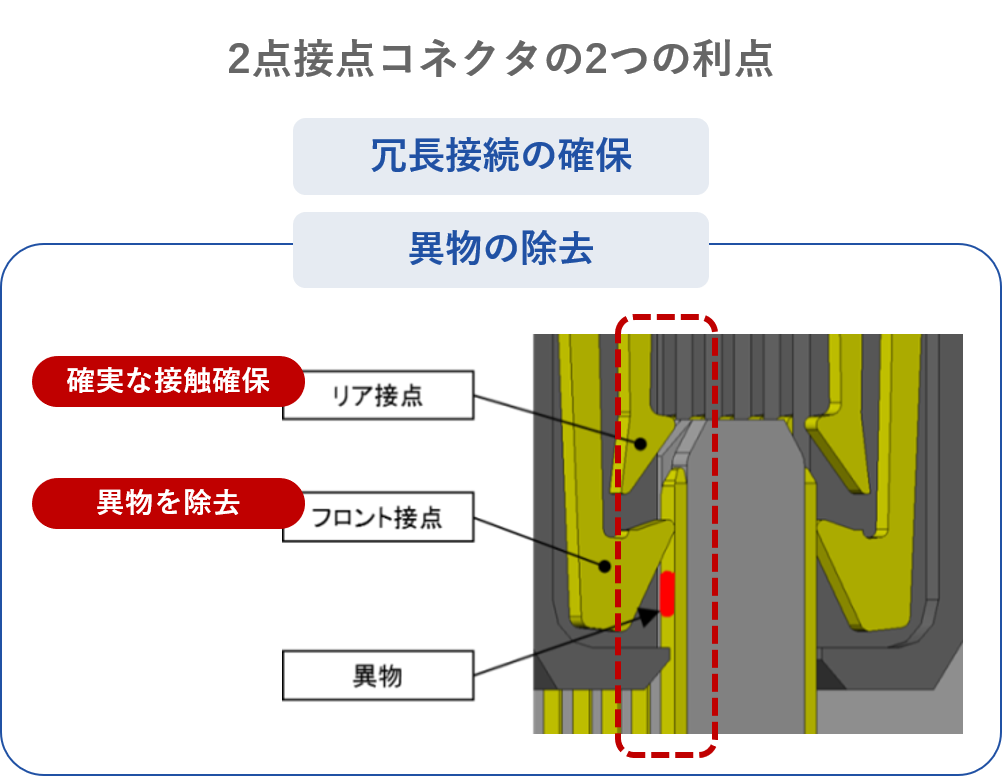

Two advantages of two-point contact connectors

Next, let's talk about the two-point contact.

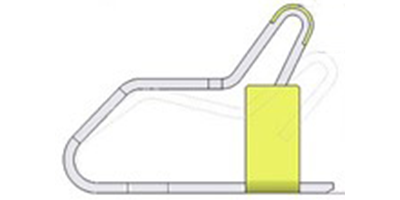

As its name suggests, it refers to a structure in which one terminal has multiple (here, two) points of contact. The two-point contact has two advantages.

The first is redundant connections. Even if one of the two points is detached, the connection can be secured with the other, which means that the risk of contact failure can be reduced.

The second is the removal of foreign matter. This is an advantage that can only be realized if it has a predetermined structure, not for all two-point contact terminals. , can ensure a reliable connection at the subsequent contacts.

Foreign matter removal by 2-point contact

In order to achieve this, it is necessary to line up the terminals, each with an independent spring, on the same straight line when mated. There are also two-point contacts that can get caught, but even if redundant connections can be secured, removal of foreign matter cannot be expected.

IRISO, we place great importance on removing foreign matter, and most two-point contact connectors have terminals with this structure. We have helped many customers solve their problems.

In this video, you can see how the two-point contact terminal actually removes foreign matter.

As for 2-point contact connectors, please refer to the 2-Point Contact structure page for more details.

Floating Connector

Next, I would like to talk about Floating Connector and Floating Board to Board Connector.

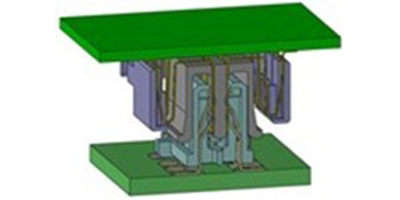

When connecting boards to each other, when multiple connectors are required to connect or when the connector position is forced due to the balance with mechanical parts, the stress caused by "positional deviation" during mounting may cause the connector to malfunction. part, especially the SMT part. In such a case, it is difficult to assemble in the first place, and even if it is assembled, problems such as cracks in the solder part may occur due to creep stress.

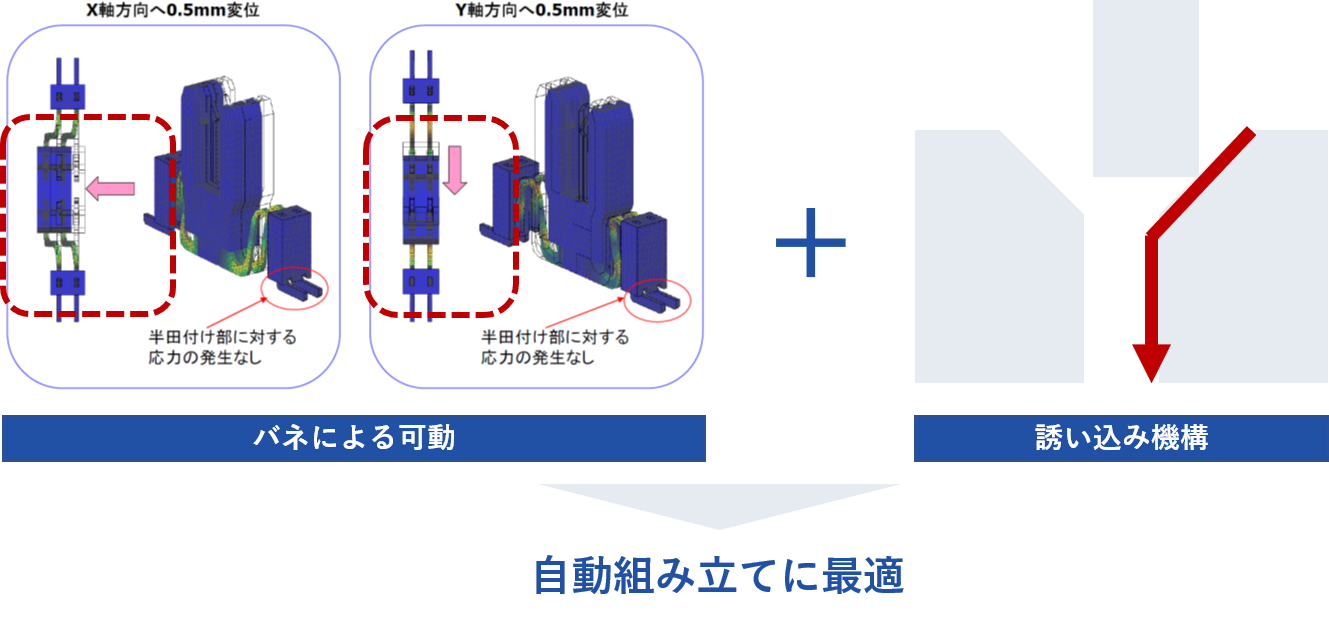

IRISO 's Robot Friendly connectors are ideal for automated assembly

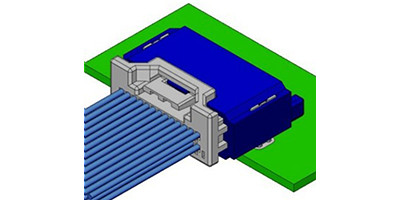

The Floating Connector, IRISO 's main product, solves this misalignment problem by having a spring in the terminal part that responds to Floating in the X Y direction.

In addition, when combined with an appropriate guiding mechanism, it improves product assembly and assembly, making it ideal for automatic assembly processes and significantly improving workability even in manual work.

Robot Friendly connector Auto-ILock also available

For automatic assembly, we also have an FPC / FFC Connectors Mating Auto I-Lock structure that can be mated in one action.

Mating with FPC/FFC with a simple insertion action is ideal for automatic mounting, making manual work easy and stable. Also, the click feeling at the time of insertion can be used as a poka-yoke for incomplete insertion.

IRISO also offers Z-Move structure, which is an evolutionary version of the Floating Connector and allows Floating in the Z-axis direction. It is also effective as a countermeasure against micro-sliding abrasion of terminals due to vibration.

High-speed transmission Connector

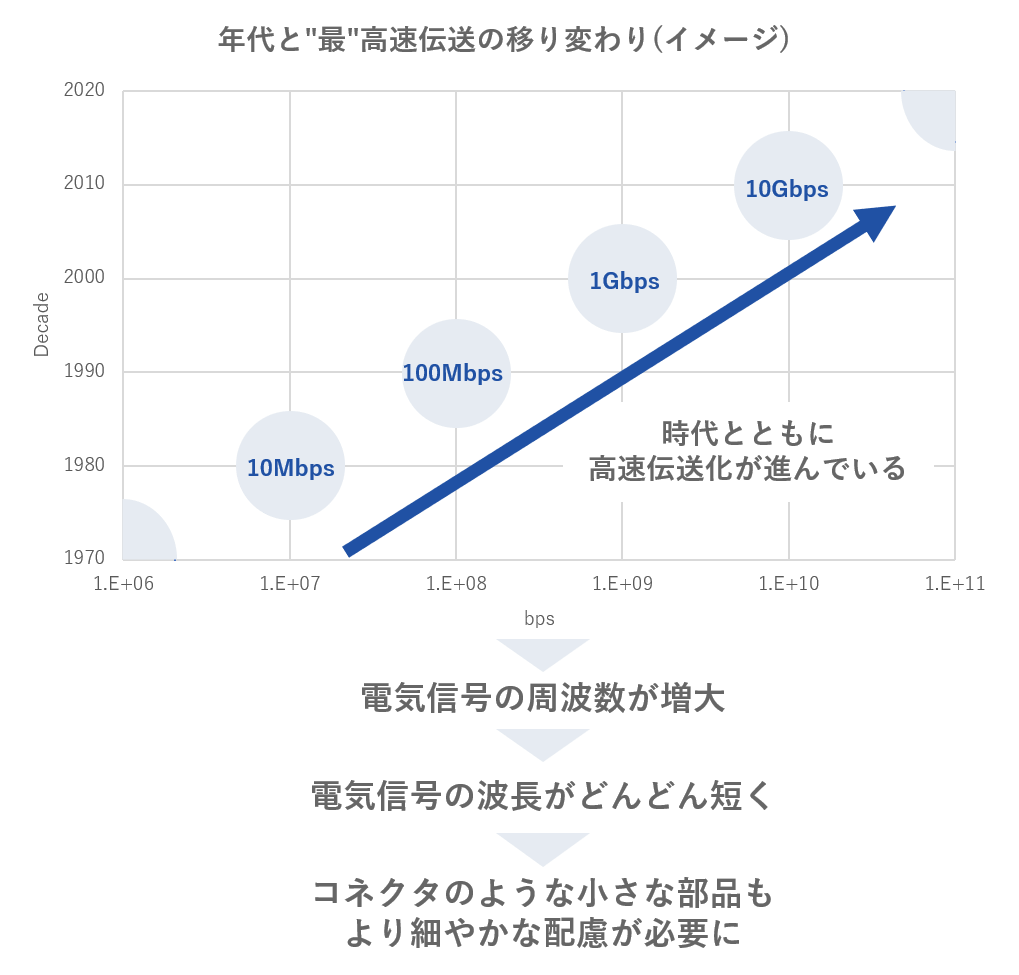

Growing demand for high-speed transmission

Finally, I would like to talk about our approach to high-speed transmission.

As electronic devices become more sophisticated and complex, the amount of information in electrical signals to be connected by connectors is increasing with the times.

That is, the frequency of electrical signals is increasing, and along with it, what is called the "length" wavelength of electrical signals is getting shorter and shorter.

What this means is that the signal is more affected by smaller or shorter transmission lines. As a result, the same problems that once occurred with telephone line transmission in units of kilometers are now occurring in units of meters in the Heisei era, and in the order of millimeters in the current Reiwa era.

So, just as we used to pay attention to board traces, wires and cables, we now need to pay more attention to smaller parts like connectors.

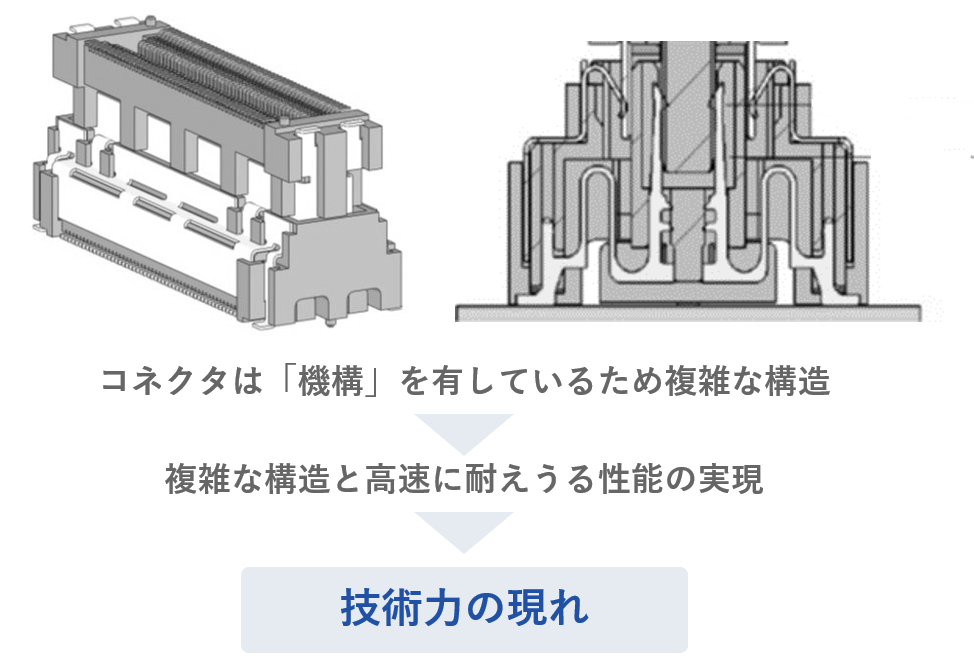

Compatibility of mechanism and transmission characteristics

Since connectors have a "mechanism", they have a more complex structure than wires or board traces.

The Floating Connector I just mentioned has a particularly complicated structure.

However, for high-speed electrical signals, it is easier to improve the performance if the structure is simple, especially for the metal part that becomes the line. Therefore, it is the manifestation of technological strength that we can achieve performance that can withstand high-speed transmission while having a complicated structure.

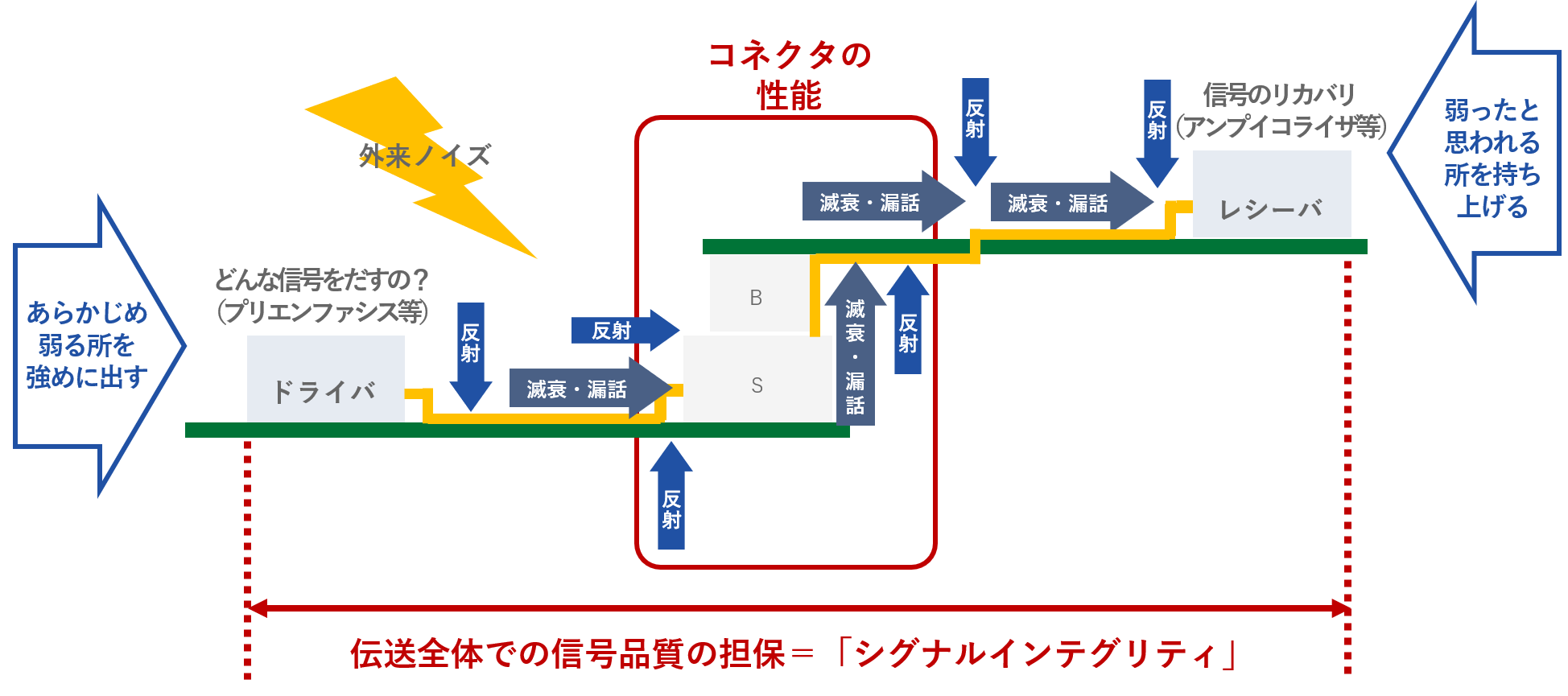

Signal integrity and connectors

Against the background of such high-speed signal transmission, the idea of "signal integrity" (let's ensure the integrity of signals) has spread since about 20 years ago. Within the concept of signal integrity, connectors are what realize the function of "connecting with a portion of the budget." From the exit of the driver to the receiver as shown, there are many factors in signal integrity considerations.

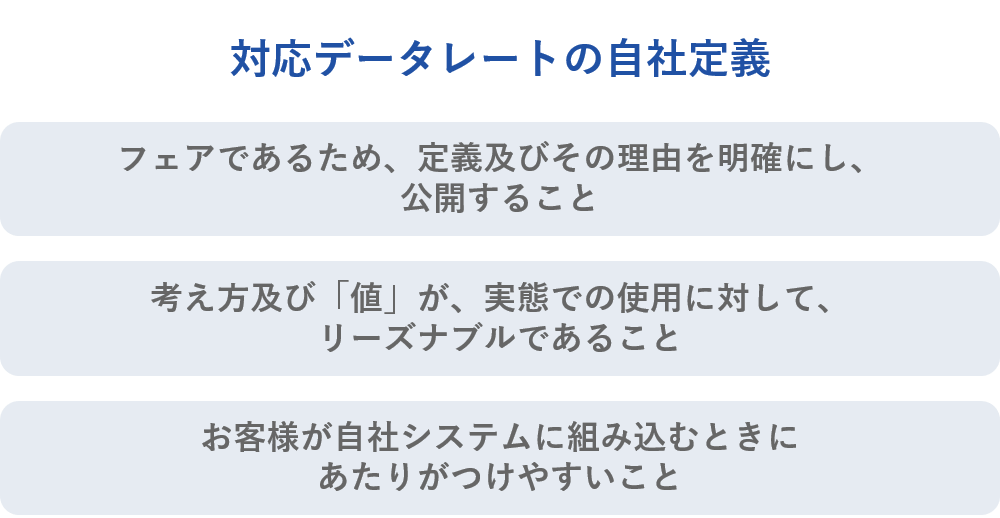

One of them is the performance of the connector. In cases where the budget is not clearly divided by standards, etc., it is not strict to determine the supported transmission speed primarily based on the performance of the connector alone. Nonetheless, we would like to provide a "reference" to make it easier for customers to choose.

For this reason, IRISO publishes its own definition along with its technical background, and attaches the corresponding data rate for each connector. We are starting this effort with Board to Board Connectors, so if you are interested, please see here.

We would love to hear your feedback on this matter. If you have any questions, please send us your comments using the inquiry form.

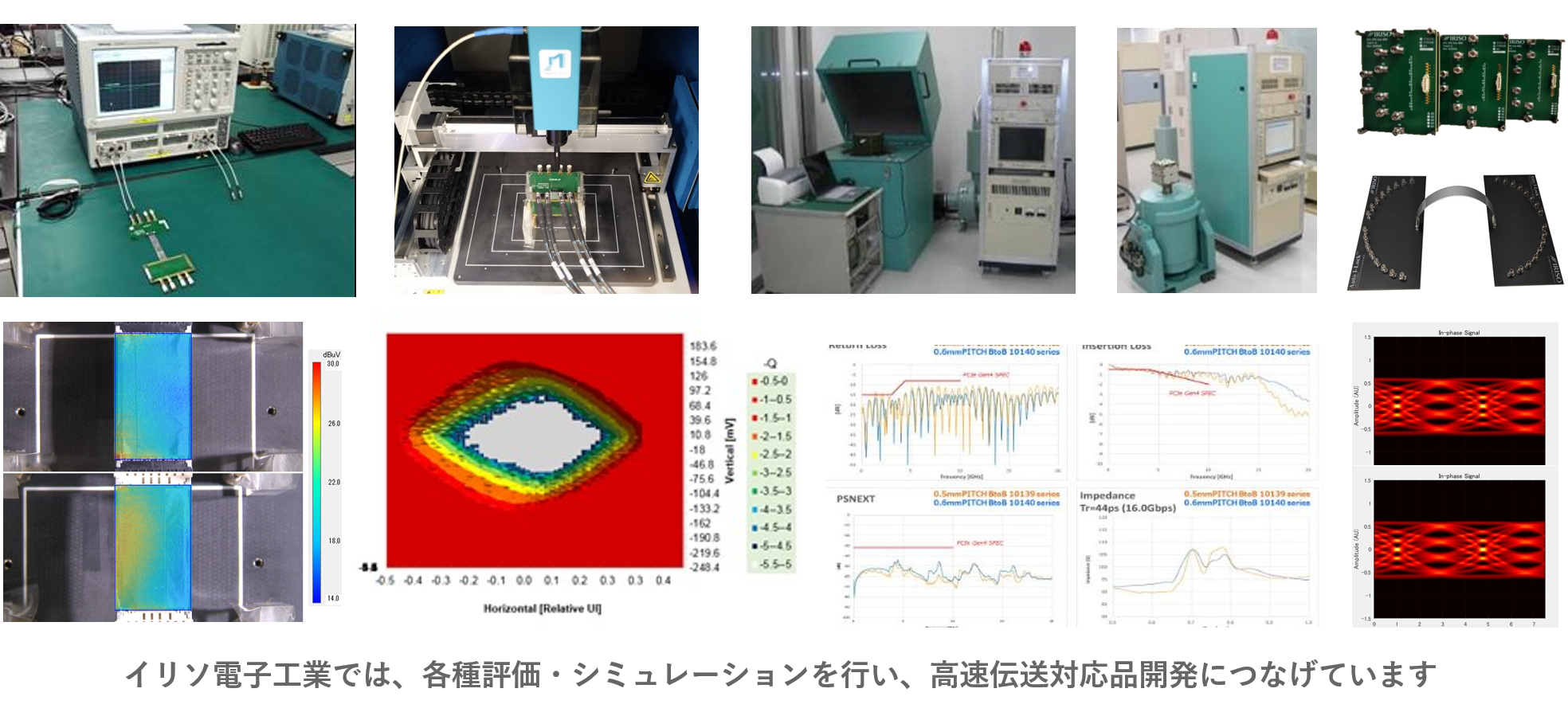

What supports the development of high-speed transmission compatible products

Of course, such efforts require products that support high-speed transmission. In order to create them, know-how such as evaluation, analysis, and simulation is important. IRISO, in addition to various parameter evaluations in the frequency domain and time domain, approximate field measurements, bit error rate measurements, electromagnetic field and circuit simulations, etc., we have enhanced evaluation simulations for mechanism and mechanical aspects that are paired with them. I am letting you. Combining such actual evaluations and simulations, and accumulating customer feedback, we use this as the foundation for developing high-speed transmission compatible products.

Here you can see our various initiatives for high-High-speed transmission Connector.

A broader description of the connector

We introduced the origins of connectors, their changes and evolution, and the efforts of IRISO.

The following articles provide extensive technical descriptions of connectors and our products. Please take a look.

Options to improve connector reliability

We will introduce "2-point contact connection" and "electrostatic shield / GND" as options for increasing the connection reliability of the connector.

How to mount the connector on the board

We will introduce the types and explain the characteristics of each type of mounting method on the connector board.

About WtoB connector and IF connector

We will explain what WtoB connectors and IF connectors are, how to attach wires to connectors, and our products.

Board to Board Connectors connection form and Floating structure

We will explain the types of Board to Board Connectors connection types, the Floating structure that prevents cracks in soldered parts, and Z-Move structure, an advanced anti-vibration solution for Floating Connector.

About Compression Terminal

We will explain the mechanism of the Compression Terminal, how to select it, options that achieve high workability and reliability, etc.

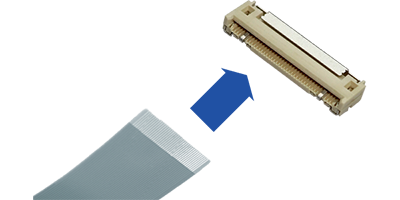

Types and features of FPC / FFC Connectors

We will explain what FPC / FFC Connectors are, and the characteristics and advantages of ZIF and NON-ZIF connectors.